Fire sponge also known as flame retardant sponge, fire cotton, flame retardant cotton, is generally a variety of polyurethane added flame retardant synthetic fire retardant materials, fire resistance: when the sponge is burning, will not produce open fire, fire sponge adopts imported flame retardant, effectively reduce the burning time, delay combustion, smoke resistance to cause the ignition place self-extinguishing.The easiest way to test this is to automatically extinguish the sponge within 6 seconds of leaving the fire

Mainly used in furniture manufacturing, massage equipment manufacturing, baby carriage manufacturing, decoration, car accessories, wall sound-absorbing, insulation pipe, fire doors and fire shutter and other aspects.

1.Water resistance: closed bubble structure, good water absorption performance.

2.Corrosion resistance: seawater, oil, weak acid and alkali and other chemicals, antibacterial, non-toxic, tasteless, no pollution.

3.Machinability: no joint, and easy to hot-pressing, cutting, gluing, laminating and other processing.

4.Shockproof: high resilience and tension resistance, strong toughness, with good shockproof/buffering performance.

5.Heat insulation, heat preservation and low temperature performance excellent, can withstand cold and sun.

6.Sound insulation: Closed bubble hole, sound insulation effect is good.

Cellulose Sponge is The best makeup product for Skin

Cellulose Sponge is The best makeup product for Skin

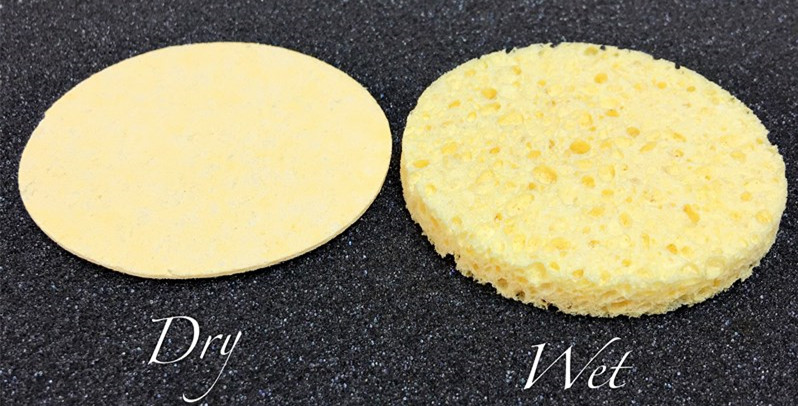

Compressed Sponge and its application

Compressed Sponge and its application

Memory Foam

Memory Foam

Filter sponge and its application

Filter sponge and its application